Joanna Kowalczyk

Project manager

t: +48 505 247 425

We build the progressive dies, manual and automatic transfers, dies and measurement gauges.

We have the extensive experience in designing for the automotive industry. We have completed projects of tools for the production of elements that are included in, among others: seats, engine covers, safety systems, car body parts. We have great technical capabilities to provide services in the field of machining. The production hall is equipped with the modern machinery and infrastructure that fulfills the highest European standards, including machining and heat treatment equipment located on the premises of the production facility, i.e.

-hardening,

-carburizing,

-nitriding,

-PVD coatings.

The stages of the implementation during the construction of the tool:

We focus on the most modern technology available on the market in the field of regeneration of injection molds and blanking dies implemented as part of JG Form Tools.

We use a laser micro tuber which compared to the classic methods of surfacing enables the repair of micro cracks or joining elements of very small shapes without causing deformation. Thanks to micro-welding we are able to regenerate the smallest micro-cracks.

What distinguishes our projects is the hybrid nature of the components. The use of tungsten carbide elements in combination with steel is a unique solution. It allows to increase the hardness and extend the life of the device.

The benefits for the client:

The JG Group team consists of specialists with many years of experience in the design and production of products for military and police purposes under the internally certified quality control system and the MSWiA concession system.

We focus on the most modern technology available in the market!

We use the latest technologies as far as the field of designing forming tools is concerned. We cooperate with CAMdivision – the largest and the only platinum partner in Poland, Siemens Digital Industries Software FY2021

Support in the construction and production of forming tools.

We invite you to cooperate with our Experts.

Project manager

t: +48 505 247 425

Mechanical Structures Engineer

t: +48 81 440 83 45

JG Form Tools - production manager

t: +48 600 882 098

The task was to implement a two-socket multi-point measuring device. The solution consisted of base elements and clamping clamps. What distinguishes our implementation is the hybrid nature of the components. The use of tungsten carbide elements in combination with steel is a unique solution. It allows to increase the hardness and extend the life of the device.

More

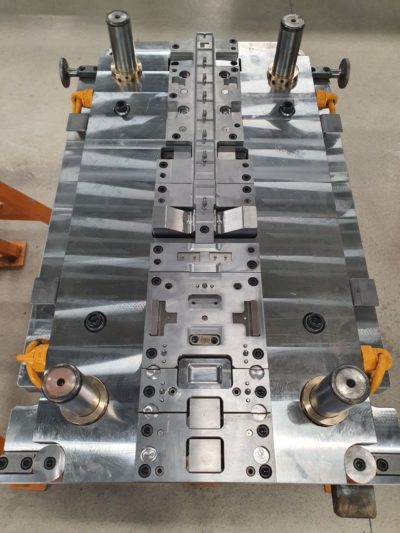

AMVIAN Automotive Sp. z o.o., a company from the #Automotive industry asked us to make a progressive tool for the production of parts that are part of the car suspension.

More

The client we have been cooperating for several years with in the field of regeneration and production of new stamping devices turned to us with an order to make new tools.

MoreDesign and execution are only part of the success!

We adjust and test each solution so that the device we manufacture would work in accordance with the expectations and requirements of the client.

In JG Group we focus on the most modern technology available in the market. The latest generation optical measuring system that we have in our machine park allows us to provide consistent, precise control of shape and dimensions throughout the entire process chain as well as reverse engineering.